New research to help nuclear power industry

1

Additive manufacturing, also known as 3D printing, has come a long way over the years. 3D-printed materials can vary widely with options that include plastic, ceramics, metals, and composites like carbon fiber. These materials make 3D printing a promising option in a wide range of industries including nuclear facilities.

3D printing metal parts is a time consuming and expensive process when compared to other materials such as plastic, and there are more efficient processes for mass production. However, 3D printing metal has a place in nuclear power plants and similar industries where parts are not mass manufactured.

While the 3D printing of metals has existed for some time, it poses technological and economic limitations. The amount of metal that can be 3D printed at any time is on the order of a kilogram an hour. However, nuclear facilities are not interested in mass-manufactured parts. It’s inefficient to make all the molds, dies, and forges required to make a single part, since every part is unique and customized. There’s also a benefit because it can print complex architectures that may not be fabricated using traditional technologies.

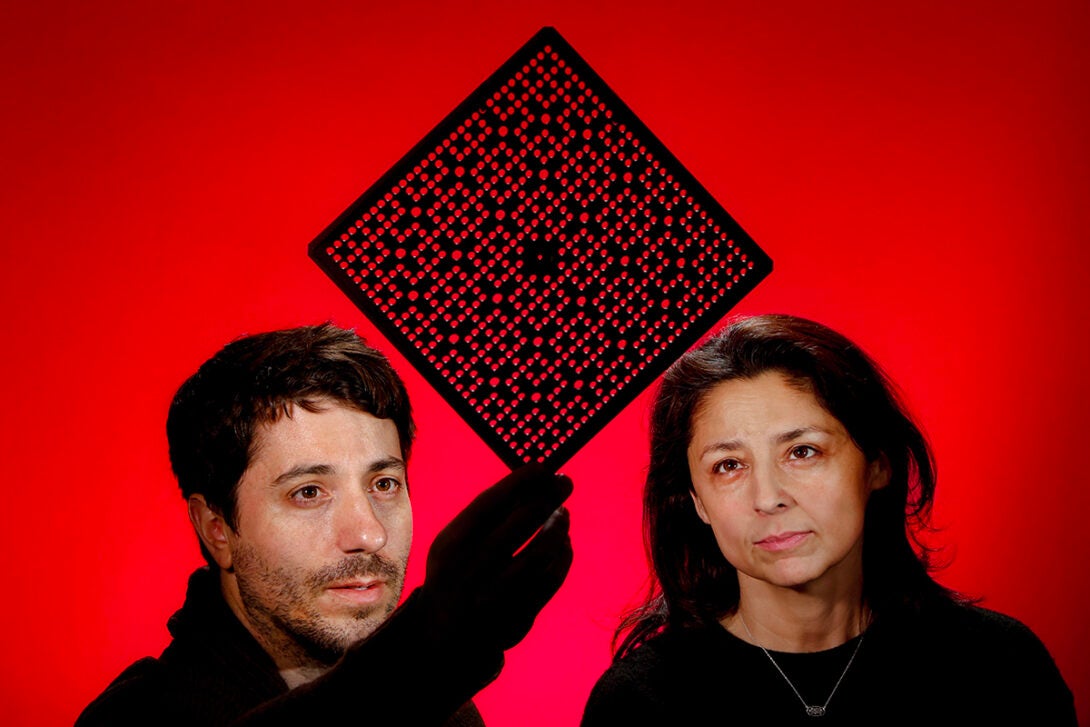

Despite the potential economic benefits of 3D printing, there are issues due to the long service life of nuclear systems. Microscale printing defects, which are difficult to avoid, raise safety concerns. UIC Professor Didem Ozevin and Assistant Professor Matthew Daly are developing new non-destructive methods to monitor defects in 3D-printed metals to ensure the reliability of the systems.

New grant, novel solutions

The UIC researchers are partnering with the University of Michigan, Argonne National Laboratory, and Westinghouse Electric Company on a three-year $1 million grant titled “Subwavelength Ultrasonic Imaging for Rapid Qualification of Additively Manufactured Nuclear Structures and Components” sponsored by the U.S. Department of Energy Nuclear Energy University Program.

“Some nuclear power plant components require fine details,” said Ozevin, director of the Nondestructive Evaluation Laboratory. “It’s complex to build with conventional casting methods, but using 3D printing may introduce some inclusions and pores, which may reduce structural capacity, and they want to make sure that they are capable of detecting them.”

“We are interested in pushing beyond plastics. Technology exists that’s translatable to work with metals and even ceramics. However, the technology is a little bit more complicated because you can’t just heat metals up and drag around a nozzle like some simple 3D printing plastic technologies,” said Daly, director of the Advanced Materials and Microstructures Lab.

Making metal parts with 3D printing uses a laser to melt and consolidate metal powders or wires as a feedstock. In the most popular method, the laser is dragged across a box of powder to draw a design and create a structure layer by layer.

“It’s like trying to take a sandbox of little powders and glue them all together to form a part,” Daly said. “While defect formation is a complicated multiphysics process, one can intuitively understand that there will be gaps between the powders if you think about trying to glue little spheres together to make a 3D structure. And that can be a problem.”

Lasting solutions

Creating parts going into a nuclear reactor must last for a long time without being handled. If the parts have tiny defects, the material’s performance and reliability may be acceptable after one week or month. However, it’s certainly a significant concern over years and decades where these tiny little defects could grow into much larger flaws, which could be a problem that threatens the reliability of the nuclear structure.

“The nuclear industry is naturally extremely risk averse. There must be a zero percent chance that these structures will unexpectedly fail. They must be extremely safe,” Daly said. “These stakeholders do not want any unforeseen failures that haven’t been mapped out. And this is where we come in. We need to detect them before they become a problem.”

Ozevin and Daly collaborated on a previous project that looked at a different type of additive manufacturing technology that works slightly differently from the metal fusion process examined here. However, the fundamental problem is the same: they had tiny defects that could become a problem further down the road that they couldn’t see with ultrasonic imaging. But they could see them when they took the piece out and cut it apart.

“In my lab, we are very good at cutting things apart to find problems, but you can’t do that for everything that’s in service,” Daly said. “We realize that there’s a need to develop new science to be able to see these defects that are below the thresholds of what exists in non-destructive imaging.”

Non-destructive imaging

Ozevin and her collaborators have made some technological progress in breaking the traditional limits of non-destructive imaging by using sensors to see defects inside structures without taking them apart. However, she noted that there are limits.

“We might be able to see a defect the size of a grain of sand, but that’s not good enough. We need to go smaller than that, because those tiny defects could become problematic much further down the road in the life of this nuclear structure,” she said.

For this project, the researchers plan to develop and improve the capability for rapid nondestructive quality assessments of additively manufactured nuclear structures and parts through advanced ultrasonic imaging with subwavelength resolution that will allow them to detect the tiniest defects.

“We will exploit the negative refraction phenomena observed in periodic structures for subwavelength focusing of acoustic waves and aim to break the diffraction limits of ultrasonic imaging for air-coupled and water-coupled configurations,” Ozevin said.

In addition to nuclear facilities, the researchers see the breakthrough being applicable in the aerospace industry, where many parts are not mass-produced and in biomedical fields for custom implants.

“If it can improve patient comfort, that’s something that people are willing to pay more for,” Daly said, which makes the economics of 3D printing attractive. “There’s enough diversity of human physiology that we can understand that not once all size fits all when it comes to something as important to your health as an implant.”