Researchers make new connection for bonding graphene oxide layers

Researchers at the University of Illinois Chicago (UIC) have made a breakthrough with bonding graphene oxide layers together.

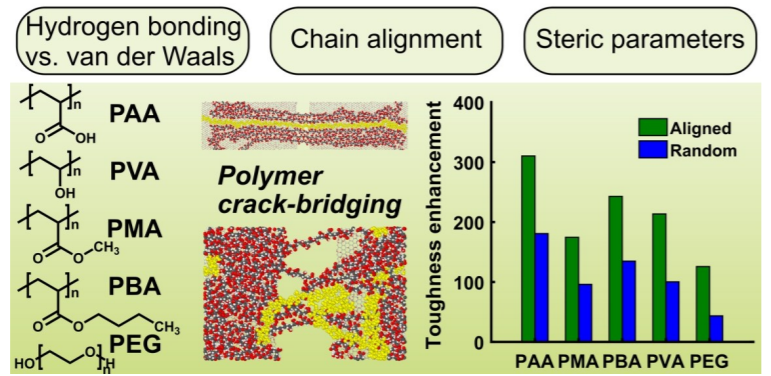

Assistant Professor Matthew Daly of the Department of Civil and Materials Engineering at UIC is the co-author of “Nanoscale toughening of ultrathin graphene oxide-polymer composites: mechanochemical insights into hydrogen-bonding/van der Waals interactions, polymer chain alignment, and steric parameters.”

The findings of the research were recently published in the journal Nanoscale, which is a high impact peer reviewed journal publishing experimental and theoretical work across the breadth of nanoscience and nanotechnology.

Two-dimensional (2D) materials have a length and width, but lack thickness or are only one layer of atoms thick.

“The 2D material we are working with is graphene oxide, and what makes it special is the bonds in the material. The bonds in the plane are very strong; basically stronger than diamond bonds. The real problems arise once you start stacking this material. As soon as you stack this material on top of each other it’s like a deck of cards. So one card on its own is hard to rip, but if you pull on a whole deck of cards you can easily cut the deck and separate individual cards. Obviously, this really problematic if we want to build structures from these materials,” said Daly.

The overall goal of the research looks at engineering materials and structures to make them lighter, but still preserve the strength. That’s good for cars, aerospace vehicles, and everything that requires lots of energy for locomotion.

“We want to scale the materials up [in thickness] to something that we can use on a physical scale. This research shows a way to stitch these materials together so they are much tougher,” said Daly.

The researchers tried a number of different polymer systems that were placed between the layers of 2D materials and determined which one worked the best. The study was done by high performance supercomputers to figure out what types of polymers best optimize the cohesion of 2D materials.

“The alignment and structure of the polymers has to be a certain way to encourage strong adhesion between the polymer and the surface it’s trying stitch together,” he said. “The results pave the way for a set of design criteria that has the potential to help remediate the problems with scalability of two-dimensional materials, which ultimately restricts potential applications.”

Daly is the director of the Advanced Materials and Microstructures Lab at UIC. Learn more about his research at amml.lab.uic.edu.